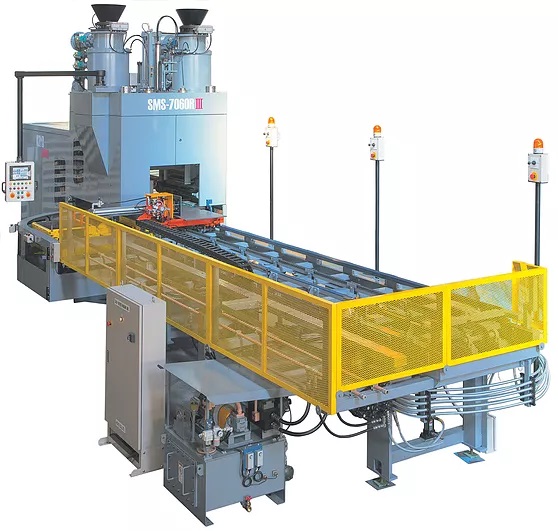

ROTORMATIC – fast mold making (150 molds per hour) with easy core setting

KOYO has unique technology for Horizontal Molding system. ROTOMATIC, 2-stations rotating drag box, makes 150 molds per hour mold production with 20 seconds core setting time.

Flexible mold handling (Flaskless Mold and Mold with Flask/Jacket)

Customer can choose molding type, flaskless mold with KOYO’s original APT-system, or flask/taper molding with Jacket and Trolly line, flexible system as per customer’s demand.

Spray nozzle in Core & Drag boxes – keep clean and reduce chemical consumption

Spraying liquid in Core & Drag boxes have a lot of efficiency, not only keeping cleanliness of facility but saving releasing agent consumption, which have good effect on machine lifetime.

Machine specifications

| Type | SMS-7060RⅢ/SMS-7060RTⅢ | SMS-6050RⅢ/SMS-6050RTⅢ | SMS-5045RⅢ/SMS-5045RTⅢ |

| Mold Size | Upper 700x600x160~250 | Upper 600x500x150~200 | Upper 500x450x160~200 |

| Lower 700x600x170~250 | Lower 600x500x150~200 | Lower 500x450x160~200 | |

| Capa. | 140 Mold/h (Core Setting 20 sec./mold included) | 150 Mold/h (Core Setting 19 sec./mold included) | 150 Mold/h (Core Setting 19 sec./mold included) |

SMS-R Series : Without Mold Frame / SMS-RT Series : With Mold Frame