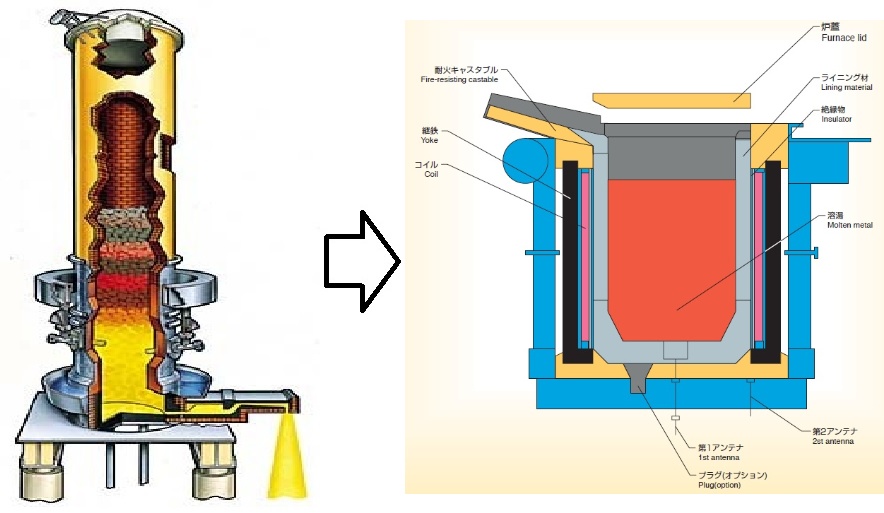

No more cupola furnace

Cupola furnace is the basic facility in foundries since BC 400, which has been melting casting iron and various kind of metal for more than 2000 years in the world. However, coke-burning cupola furnace is old-fashioned equipment nowadays, discharging lots of carbon di-oxide (CO2).

Low-Frequency vs Medium-Frequency in Induction Furnace.

Induction Furnace with Low (Utility/Power)-Frequency (50Hz or 60Hz) are quite common as smelting equipment worldwide now. However, technology development such as inverter and power-transforming could make more efficient smelting process with Medium-Frequency Induction Furnace nowadays.

Advantage of Medium-Frequency Induction Furnace.

- Fast melting speed & high production efficiency (1.4-1.6 times faster than Low-Frequency one)

- Flexible and easy operation (All molten metal to be completely discharged, which is not allowed on Low-Frequency one)

- Easy & fast start up (No special requirement such as lining material are required, at the time of operation starting)

| Type | Low Frequency | Medium Frequency |

| Frequency | 50/60Hz | 300 to 3000 Hz |

| Furnace Size | Large | Medium-Small |

| Stirring Speed | Fixed | Variable by Frequency change |

| Molten Metal Discharging | 80-90% Max | 100% possible |

| Starting Block | Required | Not required |

| Suitable for | Mono-type molten metal | Multi-type molten metal |

Why Fuji’s Medium-Frequency Induction Furnace?

Fuji Electric have long history for “Induction Heating (IH)” system development in Japan almost 100 years, and have sold more than 200 unites customers in Japan and all over the world. Technology of Induction Furnace is keep progressing always.

Fuji’s HFT series is one of the standard Induction Furnace for casting industries in Japan and Asia, high quality & low cost operation have been appreciated by lots of casting customers.